Features of canned food production

There are many questions for those who are starting to make preserves. In this article, we will discuss the topic of preservation. In this article, we will discuss the topic of preservation. In order to produce canned food, small meat processing companies should purchase two additional devices - an autoclave and a device for closing lids of metal boxes .

The purpose of sterilization is to destroy the bacteria and their spores in the canned goods.

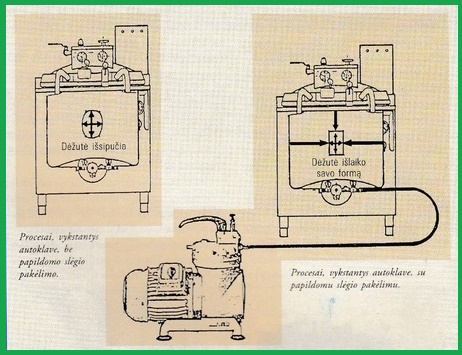

In autoclaves with pressure increase, boxes cannot be deformed during sterilization. the extra pressure prevents the boxes from bulging. The pressure is increased when the boiler heats up to 100 0C, slowly lowered when the autoclave temperature drops to 50 0C.

Sterilization of canned goods in water, autoclave with pressure function

Prepared sterilized cans are placed in autoclave baskets with the lids down. Since a certain amount of fat or gelatin may be released during sterilization, it is better to have them at the bottom of the box. This way, the consumer will see a better view of the product when he opens the can.

If a basket is used for sterilization, a perforated aluminum cover should be inserted between the rows of canning boxes. This way, the boxes are less pressed against each other. The top row of boxes must be covered with a perforated aluminum lid so that it does not wash to the surface when the autoclave dawns.

Sterilization process:

- We put the basket with boxes in the boiler. We fill the boiler with water, all boxes must be in water. It is advisable to use hot water, as it significantly shortens the heating time of the autoclave. We set the thermometer to a temperature of 105-115 0C, turn on the maximum heating.

- Close the lid of the autoclave properly. We keep the steam release valve open until the first steam appears and the temperature rises to 100 0C.

- After reaching a temperature of 100 0C, we close the steam release valve. We connect an air compressor to a special tap. With the compressor, we increase the pressure in the boiler to 1 bar. The sterilization time starts counting from this moment.

- The temperature in the boiler continues to rise, so the pressure rises slowly. The optimum pressure is reached at 1,5 bar. If the pressure continues to rise, the steam release valve should be opened and some of the steam released. If the pressure drops below 1,5 bar, the air compressor must be turned on to increase the pressure.

- At the end of the sterilization time, the heating is turned off. The autoclave starts to cool down.

- The cooling phase is very important. It must be properly controlled. The reason is that there is a pressure and temperature difference between the environment and the boiler, as well as the pressure difference between the boiler and the boxes. These pressures cannot be equalized instantly. A certain sequence and time is required to equalize the pressure and temperature differences. In devices that have a pressure mechanism, cold water can be injected into the autoclave through a special opening with a compressor. So after turning off the heating, a cold water tap is connected to the autoclave. We regulate the rising pressure in the boiler with a steam release valve and a water volume control tap. Thus, the temperature of the boiler starts to drop. We carefully monitor that the pressure inside the boiler does not drop too quickly. It can be maintained by adjusting the water level control valve. The pressure inside the boiler should drop to 1 bar within the first 10 minutes after switching off the heating.

We allow cold water to circulate inside the boiler until the temperature drops to 30 0C. Then we turn off the cold water and release the remaining pressure. Now you can open the lid of the autoclave and take out the cans.

Sterilization of canned goods in water, autoclave without pressure function

- We put canned food boxes ready to be sterilized with the lids down in the autoclave. It is better to place the boxes in such a way that the boxes in the higher row are placed on the gaps in the lower row.

- We fill with water so that all the boxes are submerged in water. It is advisable to use hot water, as it significantly shortens the heating time of the autoclave.

- We set the thermometer to a temperature of 105-115 0C, turn on the maximum heating.

- Close the lid of the autoclave properly. We keep the steam release valve open until the first steam appears and the temperature rises to 100 0C. After that, we close the steam release valve. The sterilization time starts counting from that moment.

- At the end of the sterilization time, we stop the heating. We slowly open the steam release valve. The pressure inside the boiler must not drop quickly, because the boxes may be deformed. When there is no more steam and the manometer no longer indicates boiler pressure, the autoclave lid can be opened.

Sterilization time

If we want to sterilize canned goods reliably, we need to measure the internal temperature of the contents of the boxes. It is advisable to choose a box in the very center of the autoclave and insert the temperature probe. In this way, we will be able to reliably control the sterilization process and produce high-quality preserves. Depending on what is in the boxes, their internal temperature can vary between 102-110 0C. The internal temperature of the boiler should be 5-8 0C higher.

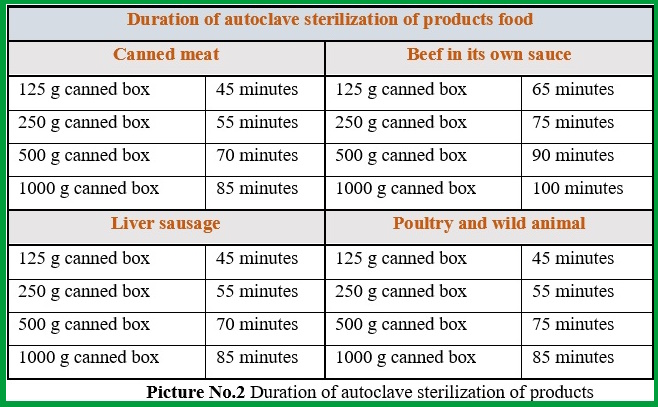

If sterilization is performed without measuring the internal temperature of the boxes, it is advisable to use the sterilization time tables below. The tables give only indicative sterilization times. When working, it is necessary to adjust the sterilization time depending on the obtained result.

Sterilization time starts counting when the steam outlet valve is closed, the internal temperature of the boiler reaches 100 0C. Sterilization is finished when the heating is stopped and the boiler starts to cool down. The sterilization times in the tables are for metal boxes. For glass containers, they should be extended by about 5 minutes.

About the autoclave manufacturer

KORIMAT

The German company Korimat Metallwarenfabrik is one of the most famous and popular autoclave manufacturers in Europe. Korimat autoclaves are universal devices and can be used not only for sterilizing canned goods, but also as a simple cooking boiler with a pressure function, as a vacuum boiler. "Korimat" boilers are heated by electricity, gas or liquid fuel. Three models enter the market - Korimat KA 160, KA 240 and KA 380. The devices have an electronic control system that automatically controls the temperature of the boiler, regulates the sterilization time. A data recording device can be connected to the boiler.